As Australia embraces electric vehicles (EVs), a pressing question comes into focus: what happens to EV batteries when they reach the end of their life? With lithium-ion batteries powering millions of EVs, recycling them sustainably is critical to reducing environmental impact and creating a circular economy for EV technology.

In this article, we explore how EV batteries are recycled, the current challenges in Australia’s recycling landscape, and the emerging solutions set to shape a cleaner EV future.

—

Table of Contents

- Why EV Battery Recycling Matters

- What’s Inside an EV Battery?

- The Battery Recycling Process Explained

- Key Challenges in Recycling EV Batteries

- The Future of Battery Recycling in Australia

- FAQs

- Conclusion

—

1. Why EV Battery Recycling Matters

EV batteries have a finite lifespan—usually 10–15 years or 160,000+ km. Once they degrade below 70–80% of their original capacity, they are no longer suitable for driving but can still hold value.

Here’s why recycling matters:

- Reduces landfill waste and environmental harm

- Recovers valuable materials like lithium, cobalt, and nickel

- Lowers demand for new mining operations

- Supports local supply chains and reduces EV production emissions

♻️ In short: effective battery recycling is essential to making EVs truly sustainable.

—

2. What’s Inside an EV Battery?

EV batteries are typically lithium-ion packs made of multiple modules and cells. They contain:

- Cathode materials: lithium, cobalt, nickel, manganese

- Anode: graphite

- Electrolytes and separators

- Casings made from aluminium or steel

- Copper wiring and control systems

⚠️ Many of these materials are non-renewable, mined in energy-intensive ways, and sometimes sourced under controversial labour practices. Recycling helps reduce this footprint.

—

3. The Battery Recycling Process Explained

EV battery recycling involves a complex series of steps:

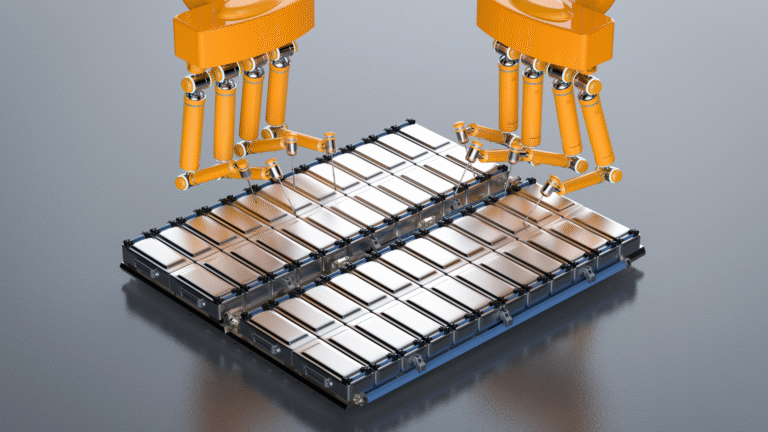

🔋 Step 1: Collection and Disassembly

- Batteries are removed from vehicles and dismantled into modules.

- Safety protocols are essential to prevent fires or chemical leaks.

🧪 Step 2: Pre-Treatment

- Batteries are discharged and shredded to break down the structure.

- Thermal or mechanical methods are used depending on the facility.

🔁 Step 3: Material Separation

- Hydrometallurgical (liquid-based) and pyrometallurgical (heat-based) techniques extract metals.

- Lithium, cobalt, nickel, and copper are recovered at varying purity levels.

📦 Step 4: Reuse or Refinement

- Materials are reused in new batteries or sold to manufacturers.

- Some cells may be repurposed for second-life use in energy storage systems.

🇦🇺 In Australia, companies like Envirostream (VIC) and Neometals are leading the development of domestic recycling capabilities.

—

4. Key Challenges in Recycling EV Batteries

While the technology exists, several hurdles must be addressed:

🛠️ Technical Complexity

- Battery designs vary between manufacturers, making standardisation difficult.

- Safe handling and transport of large lithium-ion packs remain a challenge.

📉 Low Volumes (for now)

- Most EVs on Australian roads are still relatively new; battery retirement numbers are still small, limiting economies of scale.

💰 Economic Viability

- Recycling must compete with mining on cost and efficiency.

- Currently, some processes are energy-intensive and not always profitable without subsidies or mandates.

📦 Logistics and Regulation

- Cross-border transport of used batteries is subject to hazardous waste laws.

- Australia lacks a national strategy for EV battery end-of-life management.

—

5. The Future of Battery Recycling in Australia

Australia is poised to become a global player in sustainable battery recycling due to its mineral wealth and rising EV adoption.

🔋 Key developments:

- Federal and state support for recycling infrastructure and R&D

- Circular economy initiatives under the National Battery Strategy

- Industry-led projects aiming for near-zero-waste recycling

- Local partnerships with EV manufacturers and energy providers

🧠 Innovation ahead:

- Direct recycling (recovering materials without complete breakdown)

- AI-powered sorting and automation

- Second-life applications for used EV batteries in solar or grid storage

♻️ Goal: Build a closed-loop EV battery economy where materials from retired packs go straight back into new ones—reducing emissions, mining, and waste.

—

6. FAQs

🔋 Can EV batteries be fully recycled?

Most components—including lithium, cobalt, and nickel—can be recovered, though current recovery rates vary by process. Newer methods aim for over 90% recovery.

⚡ Are old EV batteries useful for anything?

Yes. Batteries with 60–80% capacity can be used in “second-life” applications like home solar storage or grid backup systems.

🚛 Who recycles EV batteries in Australia?

Companies like Envirostream, Lithium Australia, and Neometals are active in the space, with plans to expand capabilities as EV volumes grow.

📉 Will battery recycling lower the cost of EVs?

In the long term, yes. Recycling can reduce raw material demand and supply chain costs, supporting more affordable and sustainable EV production.

—

7. Conclusion

EV battery recycling is essential to ensuring that the environmental gains of electric vehicles extend beyond their time on the road. While challenges remain, Australia is making strong progress toward a local, circular economy that reuses critical materials and minimises waste.

⚡ With innovation, investment, and regulation, recycled EV batteries won’t just be a necessity—they’ll be a national advantage.

—

Discover how EV batteries are recycled in Australia. Learn about the processes, challenges, and future of battery reuse and recycling for electric vehicles.