Battery packs are the heart of every electric vehicle (EV) — and the single component most owners worry about when thinking long term. Replacing a whole pack can be expensive, but battery technology and repair services are evolving fast. So can EV batteries be repaired rather than replaced? The short answer: sometimes — and increasingly so. This article breaks down how battery repair works, what is realistically repairable today, the economics and safety considerations, and what Australian drivers should expect.

Table of Contents

- How EV batteries are built (quick primer)

- Common battery failures and what they mean

- Repair options: module-level, cell-level, and BMS fixes

- When replacement is the only option

- Safety, certification and qualified technicians

- Economics: repair cost vs replacement vs remanufactured packs

- What this means for Australian owners and workshops

- FAQs

- Conclusion

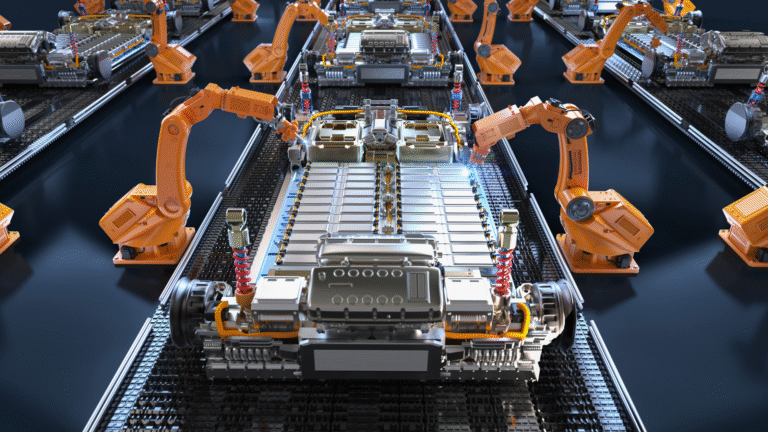

1. How EV batteries are built (quick primer)

Modern EV packs are made from many cells grouped into modules and then assembled into a pack with cooling, safety casing, and a Battery Management System (BMS). The BMS controls charging, balancing, temperature management and safety interlocks. Because packs are modular, faults are often localisable — which opens the door to repairs that don’t mean a full-pack swap.

2. Common battery failures and what they mean

- Cell degradation: Gradual capacity loss caused by age, heat, or heavy fast-charging. Usually uneven — some modules age faster.

- Cell imbalance: When groups of cells drift in state-of-charge; often a BMS or balancing fix can help.

- Thermal damage: Overheating or local thermal runaway (rare) that can physically damage modules.

- Connector, cooling or sensor faults: Failures in wiring, busbars, cooling plates or temperature sensors that affect pack performance but don’t mean the cells themselves are bad.

- Software/BMS faults: Miscalibrated BMS, lost firmware, or communication errors that mimic hardware faults.

Many “pack problems” turn out to be BMS, cooling or individual-module issues — not the whole pack.

3. Repair options: module-level, cell-level, and BMS fixes

- BMS recalibration and software fixes: Often the least invasive fix. Reflashing software, resetting balancing routines, or replacing sensors can restore performance.

- Module replacement: Swapping a few damaged modules is increasingly common. Certified modules (OEM or verified remanufactured units) can bring the pack back close to original capacity without replacing it entirely.

- Cell-level repair: Highly technical and usually done only by specialists. It involves replacing individual cells inside modules — more delicate because of safety and matching cell characteristics.

- Cooling and connector repairs: Fixing coolant leaks, replacing corroded busbars, or repairing contactors is cheaper and common.

- Reconditioning / rebalancing: For packs with imbalance or uneven degradation, balancing circuits and controlled cycling can recover usable capacity.

4. When replacement is the only option

- Severe thermal runaway or physical damage: If multiple modules are burnt, warped, or structurally compromised, safety demands a full-pack replacement.

- No compatible modules available: For some older or niche models, repair parts are scarce and a full remanufactured pack may be the only route.

- Cost threshold: If repair cost approaches replacement cost, owners and insurers will often choose replacement.

- Warranty and manufacturer rules: Some manufacturers require full pack replacement under warranty or to preserve safety certification.

5. Safety, certification and qualified technicians

Battery repair is high-risk. Correct procedures, protective equipment, HV isolation, and test protocols are essential. Repairs should be done by technicians trained in high-voltage systems and following manufacturer or accredited-industry guidelines. In Australia, using qualified, insured workshops and ensuring repairs are certified for roadworthiness is a must — both for safety and to keep warranties/insurance intact.

6. Economics: repair cost vs replacement vs remanufactured packs

- Repair (BMS fix, module swap): typically the cheapest option if the issue is local and parts are available.

- Remanufactured/Refurbished pack: Middle cost — rebuild the pack with a mix of original and reconditioned components; good when OEM parts are expensive or unavailable.

- OEM replacement: Highest cost, but comes with manufacturer warranty and guaranteed compatibility.

For many Australian owners, module-level repair or remanufactured packs offer the best balance of cost and longevity — especially as specialised repair shops scale up.

7. What this means for Australian owners and workshops

Australia’s growing EV fleet is creating a market for battery diagnostics, module refurbishment and safe decommissioning. Owners should:

- Seek diagnostic reports that identify failed modules vs pack-wide issues.

- Use accredited repairers for HV work.

- Check warranty implications before authorising any non-OEM work.

- Factor in battery repair options when buying used EVs.

Workshops that invest in training and safe facilities stand to be part of a large, sustainable repair economy rather than defaulting to wholesale replacements.

FAQs

Q: Can a single bad cell ruin a whole pack?

A: A single cell rarely destroys an entire pack, but it can cause imbalance or stress. Often module replacement or balancing solves the problem.

Q: How long does a repaired pack typically last?

A: Depends on the cause and repair quality. Module-level repairs paired with proper cooling and BMS updates can provide several more years of useful life.

Q: Is repairing an EV battery DIY-friendly?

A: No — high voltage work is dangerous and requires specialist tools and training. Always use professional services.

Conclusion

EV battery repair is a growing, practical alternative to full pack replacement. Many common faults — BMS issues, cooling failures, and individual-module degradation — can be repaired economically and safely when handled by qualified technicians. For Australian owners, this means better repair options, lower lifetime costs and more confidence buying used EVs — provided repairs are certified and performed to high safety standards.

Meta description: Can EV batteries be repaired instead of replaced? Discover module repairs, BMS fixes, safety rules and what Australian owners should expect when batteries fail.